공동활용장비

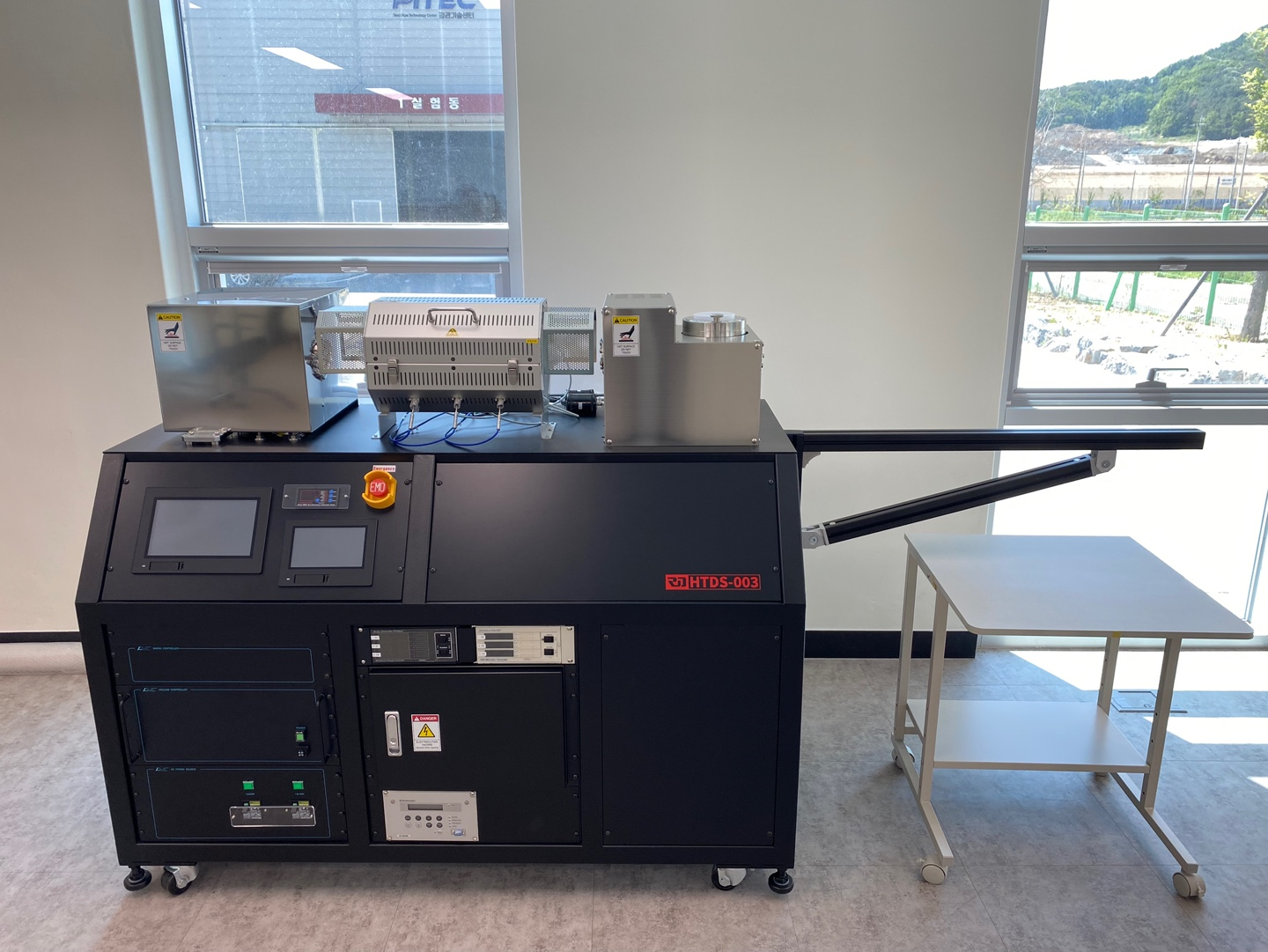

- Diffusible hydrogen analyzer for steel pipe

- 강관 확산수소 분석기

- i-Tube No. 2204-B-0232

- NTIS No NFEC-2022-06-279818

- 설치기관 재단법인포항소재산업진흥원

- 주소 경상북도 포항시 남구 동해면 블루밸리동로 178 (공당리)

- 담당자 박주은 (T. )

- 매뉴얼

-

온라인* 본 장비는 온라인 예약이 불가하오니 장비사용 예약과 관련해서는

예약가능여부

장비 보유기관에 직접 문의 주시기 바랍니다. (장비 예약은 Zeus 시스템에서 회원가입후 예약가능)

장비정보

-

제작사

R-DEC

-

모델 명

HTDS-003

내용연수10년

-

구분

주장비

용도시험

-

표준 분류

화합물 전처리·분석장비 > 질량분석장비 > 달리 분류되지 않는 질량분석장비

장비활용범위공동활용서비스

-

취득일

2022-04-20

취득금액268,821,280원

- 인증정보

- 기능

- 장비 상세설명

이용안내

-

사용형태

기관의뢰

설치형태고정형

-

사용료 형태

건별

장비 사용료[EA] 50,000원

장비설명

금속시편에 포함된 수소의 질량을 측정하거나 분석하는 장비

고감도의 Q-MS(Quadruple Mass Spectrometer)을 장착하여 정밀한 측정이 가능

터치 패널 컨트롤러가 장착되어 조작이 용이하며, 인터록기능을 통하여 장비 사용자의 안전을 보장

장비 구성 및 성능

1. Analysis Chamber (Q-Mass)

1-1 Analyzer

a) Analyzer : Quarupole Mass Spectrometer (Microvision2)

b) Sensitivity: 0.01ppmw (5g sample)

c) Dynamic range: 1 to 100 a.m.u.

d) Detection method: Dual method (Faraday Cup/SEM 전환방식)

e) Hydrogen background: 5.0 x 10-9Pa or lower

f) Resolution: <10% Valley

g) Ionizer: UHV ion source

1-2 Pumping Capability

a) Ultimate pressure: 5 x 10-8Pa or lower

b) Hydrogen background: 5.0 x 10-9Pa or lower

1-3 Vacuum Pump (Tandem Turbo Molecular Pumps)

a) Main pumps

1. Magnetically-levitated Turbo Molecular Pump (TMP)

(Pumping speed: 320L/s with N2)

(Pump itself: 5 x 10-8Pa or lower)

(Operable Pressure: 1.3~10-8Pa order)

2. Turbo Molecular Pump (TMP)

(Pumping speed: 70L/s with N2)

(Pump itself: 10-7Pa order)

b) Sub (Roughing) pump

1. Oil-sealed rotary pump (Located outside of system frame)

2. Pumping speed: 200L/min

(Pump itself: 2 x 10-1Pa or lower)

1-4 Analysis Chamber (UHV type)

a) Material: SUS 304

b) Inner surface treatment: Electrolytic compound polishing

c) Degassing: 450 deg.C for 10 hrs

d) Connect Flanges: Conflat flanges (CFF) with metal gaskets (UHV type)

f) Baking temp.: 200 deg.C

g) Isolation device: UHV All metal gate valve between the Analysis chamber

and the Sample Heating Furnace

1-5 Vacuum Pressure Gauge

a) Nude Ion Gauge

b) Pressure range: 10-2 Pa to 3 x 10-9Pa order

1-6 Standard Leak Gas (inject Hydrogen from the furnace)

a) 0.01 ppm (weight %) of Hydrogen can be confirmed.

b) The gas will be injected through All Metal Leak Valve (manual type).

c) The pressure of the Standard Leak Gas Chamber will be stabilized by

the absolute pressure gauge.

d) Leakage: 5.00kPa = 9.24×10-6 atm・cc/S (Degree)

25.00kPa = 4.60×10-5 atm・cc/S (Degree)

50.00kPa = 9.30×10-5 atm・cc/S (Degree)

100.00kPa = 1.90×10-4 atm・cc/S (Degree)

2. Sample Heating Furnace

2-1 Sample Size and Loading Sample

a) Max. sample size: φ20mm x L50mm (No shape restriction)

2-2 Electrical Resistive Heating Furnace

a) Furnace: 2 Divisions, Open/Close type

b) Max. Temperature: 1,000 deg.C (Soaking length: 200mm ±5℃)

c) Heater: 2kW, AC200V

d) Heating Zone: 3 Heating Zones (Uniformity=100mm)

e) Dimensions of Furnace: W300 × D450 × H350mm

f) Dimensions of Reactor: φ40mm × 300mm (length)

g) Dimensions of Reactor Core Tube: φ33mm × φ30mm

2-3 Touch Panel Heater Controller

a) Temp. Set/Ramp Rate Set: Touch panel operation

b) Control Method: PID control with Thermocouple (T/C)

c) Output: 0 to 10V analog output (output to Q-MS)

d) Temp. Ramp Rate Control: Adjustable between 50℃/hr and 600℃/hr

3. Load-Lock Chamber (Preparation Chamber)

3-1 Pumping Capability

a) Max pressure: 5×10-5 Pa or lower

* Time required from sample introduction to evacuation: assuming less than

15 minutes

3-2 Vacuum Pump

a) Main pump

Turbo Molecular Pump (TMP)

(Pumping speed: 280L/s with N2)

b) Sub pump

Oil-sealed rotary pump (Located outside of system frame)

(Pumping speed: 80L/min with N2)

3-3 Load-lock Chamber (UHV)

a) Material: SUS304

b) Surface treatment: Electrochemical polish finish

c) Connect flange: Conflat flanges (CFF) with metal gaskets (UHV type)

d) Baking temperature: 150 deg.C

e) Isolation Device: UHV All metal valve between the load lcok chamber and

the Sample Heating Furnace

3-4 Vacuum Gauge

a) BA(Bayard-Alpert) ionization gauge

Measurement range: 1 Pa~10-7 Pa order

3-5 Sample Introduction Method

a) Using the touch panel, operate the leak valve to purge the chamber w/ N2.

b) Open the hatch to place a sample. Close the hatch.

c) Evacuate the chamber using the touch panel controller.

3-6 Sample Transfer Method

a) Open the gate valve between the Load-lock chamber and the Analysis

chamber.

Use the transfer rod and deliver the sample to the center of the furnace.

b) After the measurement, remove the sample by operating the transfer rod and

the gate valve.

4. Pumping Controller (Baking System)

a) Manual operation of pumping & valve control for Analysis and Load-Lock

chamber

b) Automated operation of pumping & valve control for Analysis and Load-Lock

chamber

c) Vacuum leak operation for Load-Lock chamber.

d) Automated operation of standard leak hydrogen gas introduction and

pumping of gas lines.

e) Temperature setting/control during baking process of vacuum chamber.

Set point signals from vacuum gauges and/or various interlock switches will

help the user to operate the system safely.

5. Hydrogen Data Acquisition System

5-1 Software

a) Q-mass Control Software (Process Eye Professional)

b) Hydrogen Mass Calculation Software (H2 Cal)

c) Display of desorbed hydrogen spectra

d) Calculation of hydrogen mass in a selected temperature range

e) Subtraction of hydrogen background and Calculation of hydrogen mass in

sample (Unit: ppm wt)

5-2 Hardware

a) CPU: Core i5 3.0GHz / 6MB

b) OS: Windows 10 Pro 64bit (English version)

(Office Home and Business 2019)

c) HD: 500GB

6. Accessories

The warranty period of following parts shall be 1 year.

- Oil for Rotary pump (4L) -------------- 1ea

- Alumina for fore-line trap -------------- 1ea

- Spare Cartridge for Oil-mist filter --- 1ea

- Cu Gasket φ34CFF ------------------ 10ea

- Cu Gasket φ70CFF ------------------ 10ea

- Cu Gasket φ152CFF ------------------ 10ea

- 4VCR Gasket ----------------------------- 5ea

- 8VCR Gasket ----------------------------- 5ea