공동활용장비

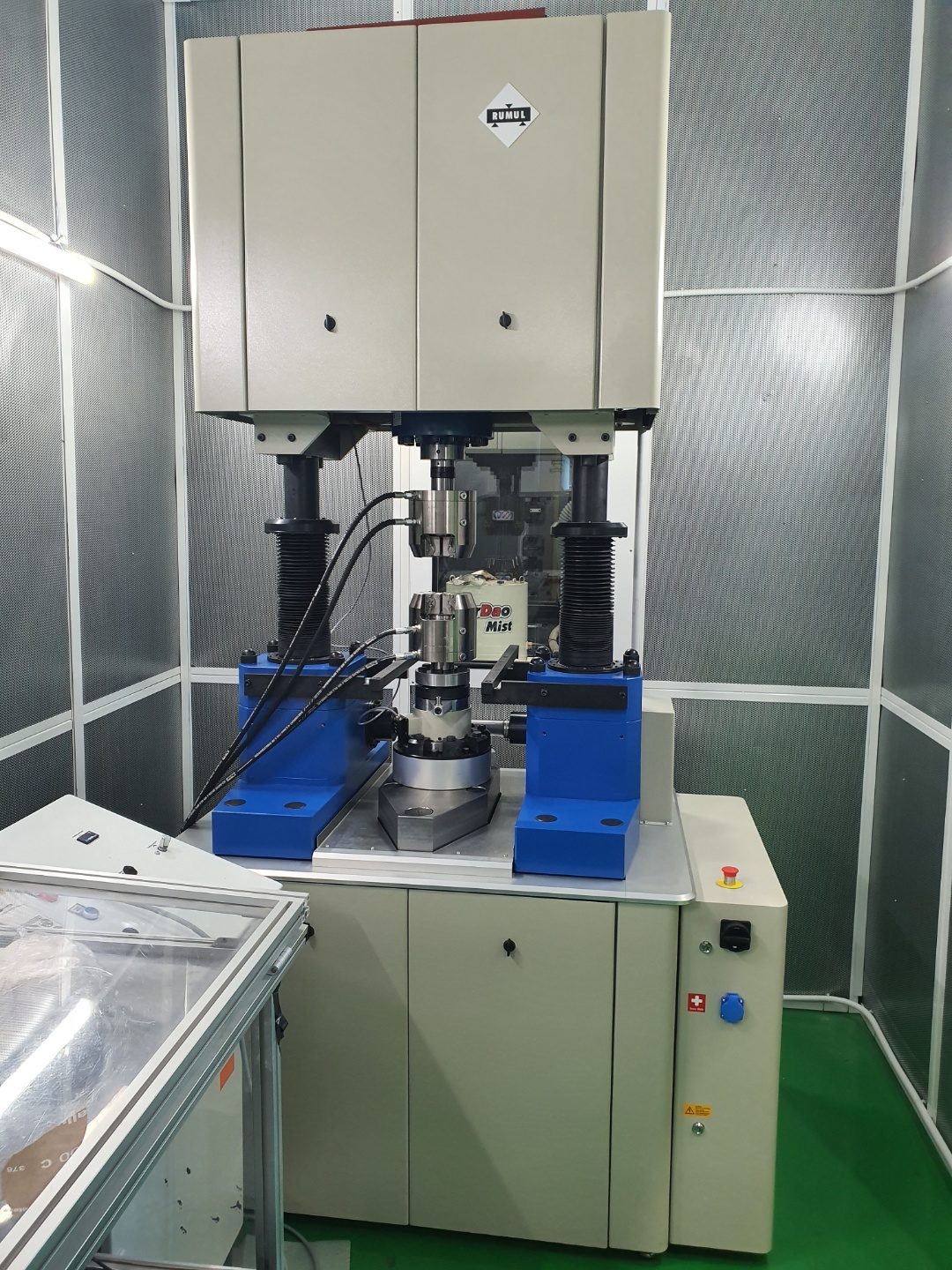

- High capa. High cycle Fatigue Testing Machine

- 고용량 고주기 피로시험기

- i-Tube No. 2001-C-0134

- NTIS No NFEC-2020-01-260129

-

설치기관

순천뿌리기술지원센터

(한국생산기술연구원)

- 주소 전라남도 순천시 해룡면 해룡산단2로 34 (선월리)

- 담당자 유효상 (T. 041-589-8114 )

- 매뉴얼

-

온라인* 본 장비는 온라인 예약이 불가하오니 장비사용 예약과 관련해서는

예약가능여부

장비 보유기관에 직접 문의 주시기 바랍니다. (장비 예약은 Zeus 시스템에서 회원가입후 예약가능)

장비정보

-

제작사

RUMUL

-

모델 명

VIBRO-FORTE 700kN

내용연수11년

-

구분

주장비

용도시험

-

표준 분류

기계가공·시험장비 > 재료물성시험장비 > 만능피로시험기

-

취득일

2020-01-06

취득금액477,224,000원

- 인증정보

- 기능

- 장비 상세설명

이용안내

-

사용형태

기관의뢰

설치형태고정형

-

사용료 형태

건별

장비 사용료5,000,000원

장비설명

자기공명(마그네트에서 전류발생시켜 자장형성)을 이용하여 주파수 발생하는 장비로 부품/소재의 동적 피로 내구 강도 확보를 위한 재료물성과 관련된 부품/소재의 피로 강성과 파괴의 상관관계해석에 활용함

장비 구성 및 성능

A. main system

1. Main body equipped with static and dynamic loading system

1-1) Max. Dynamic Peak Load : 700 kN or more

1-2) Max. Static Load : 550 kN tension/compression or more

1-3) Load amplitude : ± 275 kN or more

1-4) Elastic extension of the specimen in dynamic : ±2 mm(total 4 mm) or more

1-5) Working frequency range : 50 ~ 150 Hz or more

1-6) Frequency steps : 4 steps or more

1-7) Distance between mounting table and load cell : Max. 1100 mm or more

1-8) Clearance between columns : 700 mm or more

1-9) The machine basic body shall be compact, with a total weight of less than 5 tons for the convenience of the installation site, so that the machine can be easily moved by the forklift.

1-10) Accuracy of control load : ±0.5% or better in static and dynamic from 10kN upto 700kN

1-11) Accuracy of frequency measuring : ±0.001Hz or better

1-12) Frequency drop detection: ±0.005Hz or better

1-13) Alignment error : 5% or better according ISO 7500-I

1-14) Max. cross head up & down speed : 90 mm/min or more.

1-15) Load cell should integrate acceleration transducer in order to compensate mass forces and should be mountable on the machine table or on the oscillation head.

2. Machine controller

2-1) measuring amplifiers for load and stroke

2-2) digital converters

2-3) The integrated process computer is responsible for online measuring, data processing and controlling servoamplifiers for static and dynamic drive

2-5) Remote control including digital display of all test parameters for easy test set-up

2-6) Online multichannel oscilloscope

2-7) 8 digital in and out channels or more and 4 universally programmable relais

2-8)10 analog in channels and 6 analog out channels (+/- 10 V)

2-9) 1 temperature in channel for thermoelement type K

2-10)Multichannel high speed data acquisition rate of 25 kHz(or higher) with 24 Bit resolution and 64 Bit signal processing with automatic data stream of each load cycle at test start, test stop and at chosen events

2-11) self-diagnosis functions

3. Operator terminal

3-1) The operator terminal computer is a commercial computer with MS‐WINDOWS operating system. It runs various application programs and communicates with machine via standard interface (Ethernet)

3-2) 24“‐monitor to display the relevant data of the test

3-3) keyboard and mouse for entering commands

3-4) touch-screen remote control for main functions with integrated digital display for static and dynamic load, stroke and crosshead position for operating the machine during set-up

3-5) Table for PC

4. Software programs

- 상용 Software: Windows 10

- 장비 전용 Software

4-1) Basic fatigue testing program (or equivalent)

- monitoring the machine with different possible reactions: message, alarm, stop, load, frequency, frequency travel, power

- display of frequency drop (frequency tripping)

* The resonant frequency which is depending on specimen’s stiffness and therefore also on the crack length shall be measured and compared with a preselected value. The machine will be switched off as soon as the frequency reaches the set value.

- online help system

- saving of test and software settings in test schemes

- saving of intermediate results in records defined by user.

- storage either in intervals or depending on events.

- graphical and numerical record of complete test (History)

- LAN integration with messaging

4-2) Precracking program of notched specimens(or equivalent) with decreasing load steps for fracture mechanics tests. Each step corresponds with a certain fatigue crack growth and the appropriate change in frequency will indicate the end of a step. Protocol to document the precracking process (step, load, r-ratio, number of stress cycles).

4-3) Fatigue crack growth program according to ASTM E 647(or equivalent) controlling of the machine to run the test via the stress intensity down to K-Threshold. Program supports various fracture mechanic specimen as per ASTM and specimens with free eligible geometry functions

- Various control modes:

∆ decreasing with Kmax, Kmid or R constant

∆ increasing with Kmax, Kmid or R constant

constant ∆

constant load

- Different inputs of the crack length measurement:

external signal (i.e. drop method)

compliance (load vs COD)

DCPD(Direct Current Potential Drop) or ACPD(Alternative Current Potential Drop) crack measurement system

- Recording of crack closure effects

- Editing of test results

- comfortable adaption and graphical online display of the results

- graphical display with “Copy and Paste“ to be used in WINDOWS applications

- saving of test relevant data