공동활용장비

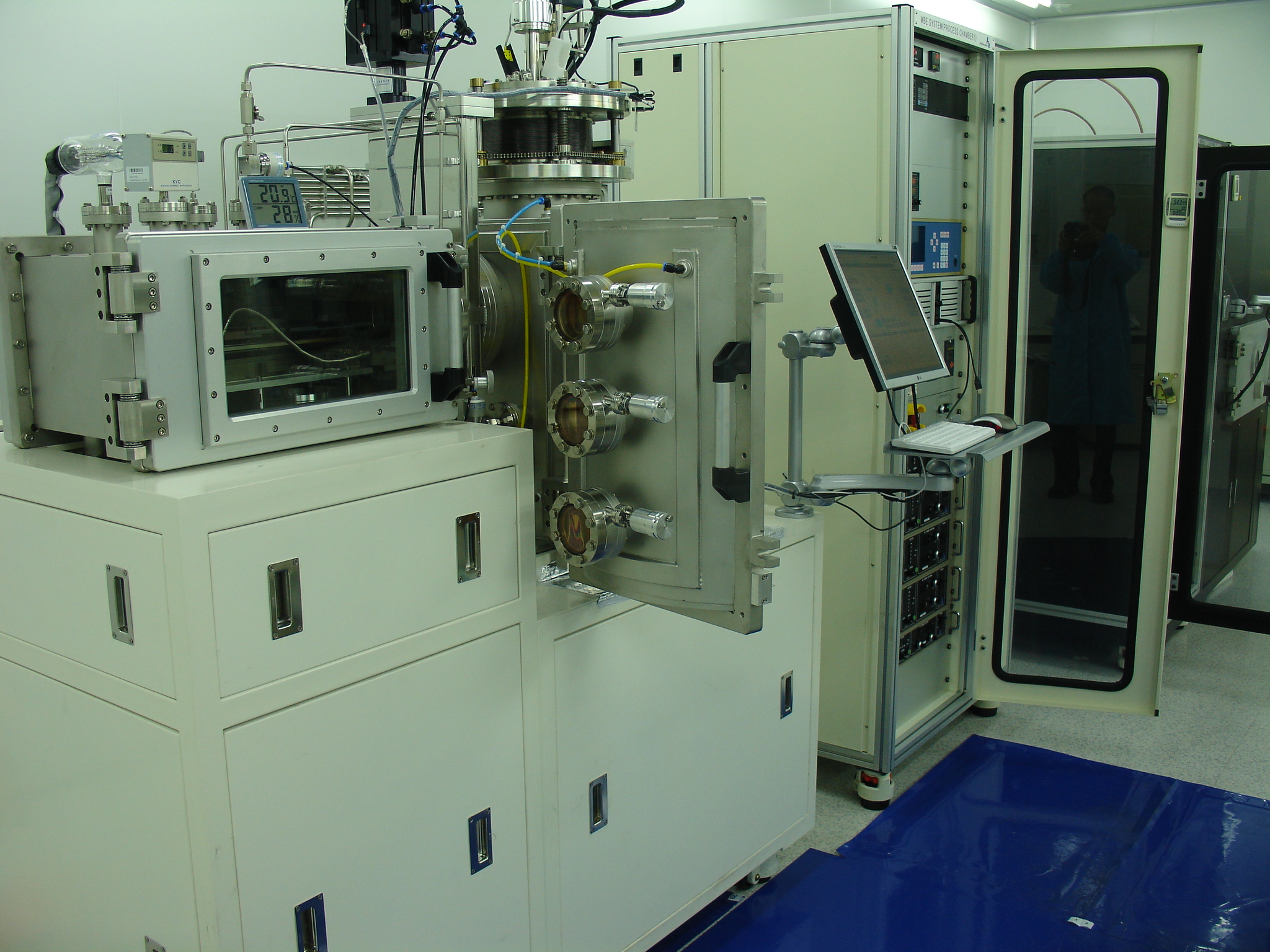

- Molecular Beam Epitaxy

- 분자빔박막성장시스템

- i-Tube No. 0809-Z-0047

- NTIS No NFEC-2010-12-129884

-

설치기관

나노융합실용화센터

((재)대구테크노파크나노융합실용화센터)

- 주소 대구광역시 달서구 성서공단로 46-17,대구테크노파크 나노융합실용화센터(대천동)

- 담당자 이재근 (T. 053-602-1780 )

- 매뉴얼

-

온라인* 본 장비는 온라인 예약이 불가하오니 장비사용 예약과 관련해서는

예약가능여부

장비 보유기관에 직접 문의 주시기 바랍니다. (장비 예약은 Zeus 시스템에서 회원가입후 예약가능)

장비정보

-

제작사

알파플러스

-

모델 명

MBE system

내용연수10년

-

구분

주장비

용도시험

-

표준 분류

기계가공·시험장비 > 반도체장비 > 열증착기

-

취득일

2008-09-15

취득금액409,677,240원

- 인증정보

- 기능

- 장비 상세설명

이용안내

-

사용형태

기관의뢰

설치형태고정형

-

사용료 형태

건별

장비 사용료50,000원

장비설명

Vacuum chamber: 2 loadlock, process chamber I and process chamber II- Ultimate pressure for system: 5 × 10-10 Torr within 12 hours- Base pressure for film process: 1 × 10-8 Torr within 30 minutes - Deposition material: Cu, In, Ga, Se, Mo, intrinsic, n and p type ZnO, etc- Substrate material: Glass and flexible substrate- Substrate heating, cooling method: Max. 1,200 ℃, water cooling - Thickness uniformity of thin film: ≤± 3% on 100 × 100 mm2- Deposition control rate: 0.1 - 50 Å/sec- Process time and deposition rate: 0.5 Å/sec during 60 minutes- Temperature of effusion cell: Max. up to 1,800 ℃- Process recipe control: Automatic deposition control program depend on multi deposition rate, time, substrate temperature, heating and cooling function

장비 구성 및 성능

Vacuum chamber: 2 loadlock, process chamber I and process chamber II- Ultimate pressure for system: 5 × 10-10 Torr within 12 hours- Base pressure for film process: 1 × 10-8 Torr within 30 minutes - Deposition material: Cu, In, Ga, Se, Mo, intrinsic, n and p type ZnO, etc- Substrate material: Glass and flexible substrate- Substrate heating, cooling method: Max. 1,200 ℃, water cooling - Thickness uniformity of thin film: ≤± 3% on 100 × 100 mm2- Deposition control rate: 0.1 - 50 Å/sec- Process time and deposition rate: 0.5 Å/sec during 60 minutes- Temperature of effusion cell: Max. up to 1,800 ℃- Process recipe control: Automatic deposition control program depend on multi deposition rate, time, substrate temperature, heating and cooling function